Power chips are linked to exterior circuits with packaging, and their performance relies on the support of the product packaging. In high-power scenarios, power chips are usually packaged as power modules. Chip affiliation describes the electric connection on the upper surface of the chip, which is generally aluminum bonding cable in typical modules. ^

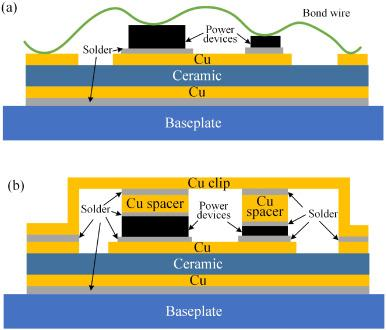

Typical power component bundle cross-section

At present, industrial silicon carbide power modules still primarily utilize the packaging technology of this wire-bonded typical silicon IGBT component. They encounter issues such as huge high-frequency parasitical parameters, not enough warmth dissipation capability, low-temperature resistance, and inadequate insulation strength, which restrict making use of silicon carbide semiconductors. The screen of excellent performance. In order to resolve these problems and completely exploit the substantial potential benefits of silicon carbide chips, many new packaging modern technologies and options for silicon carbide power modules have actually emerged in recent years.

Silicon carbide power module bonding technique

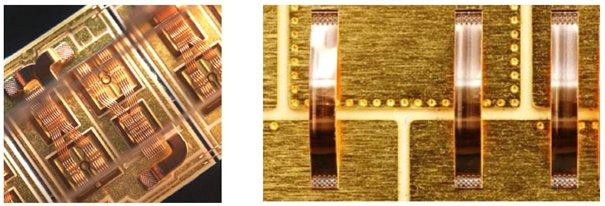

(Figure (a) Wire bonding and (b) Cu Clip power module structure diagram (left) copper wire and (right) copper strip connection process)

Bonding products have actually developed from gold cable bonding in 2001 to aluminum cable (tape) bonding in 2006, copper cord bonding in 2011, and Cu Clip bonding in 2016. Low-power tools have developed from gold cords to copper cables, and the driving pressure is cost reduction; high-power devices have actually established from aluminum cords (strips) to Cu Clips, and the driving force is to enhance item efficiency. The better the power, the greater the needs.

Cu Clip is copper strip, copper sheet. Clip Bond, or strip bonding, is a product packaging procedure that utilizes a solid copper bridge soldered to solder to attach chips and pins. Compared with typical bonding product packaging approaches, Cu Clip technology has the following benefits:

1. The connection in between the chip and the pins is made of copper sheets, which, to a certain extent, replaces the conventional wire bonding technique between the chip and the pins. Therefore, an unique bundle resistance value, higher present flow, and better thermal conductivity can be acquired.

2. The lead pin welding location does not need to be silver-plated, which can fully save the cost of silver plating and bad silver plating.

3. The product appearance is entirely regular with normal items and is mainly made use of in servers, mobile computers, batteries/drives, graphics cards, motors, power supplies, and various other fields.

Cu Clip has 2 bonding approaches.

All copper sheet bonding technique

Both the Gate pad and the Source pad are clip-based. This bonding technique is more expensive and complex, yet it can attain better Rdson and much better thermal results.

( copper strip)

Copper sheet plus wire bonding technique

The source pad uses a Clip method, and the Gate makes use of a Cord method. This bonding technique is a little less costly than the all-copper bonding approach, conserving wafer location (suitable to very tiny gate areas). The procedure is less complex than the all-copper bonding technique and can get much better Rdson and better thermal impact.

Provider of Copper Strip

TRUNNANOÂ is a supplier of surfactant with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are finding scrap copper prices near me, please feel free to contact us and send an inquiry.

Inquiry us