Titanium steel alloy plate is a high-performance composite product that integrates the outstanding properties of titanium and steel. Titanium is recognized for its high stamina, reduced thickness, deterioration resistance and excellent biocompatibility, while steel has excellent mechanical toughness and processability. Via a certain alloying process, titanium steel alloy layers not just inherit the benefits of these two materials yet also have higher total efficiency. Its main performance attributes include high strength and light-weight, low thickness yet very high toughness, appropriate for minimizing weight while keeping sufficient structural toughness, very corrosion-resistant, and can maintain great efficiency also in extreme atmospheres. Suitable for marine design and chemical tools and various other fields; good thermal stability can still maintain excellent mechanical residential properties at heats, appropriate for aerospace and high-temperature industrial atmospheres; excellent handling performance can be cut and welded by conventional steel processing methods and molding to promote the manufacture of complex-shaped components. Titanium steel alloy plates are widely utilized in lots of fields, including aerospace (used to manufacture airplane structural parts, engine elements, and so on, to improve gas effectiveness and security), sea engineering (used to construct deep-sea drilling platforms, ship coverings, and so on, to withstand salt water deterioration), vehicle manufacturing (particularly in the area of electrical cars, utilized to make body and framework components to accomplish light-weight design) and medical devices (used to make artificial joints, oral implants, and so on, to improve patient comfort and service life).

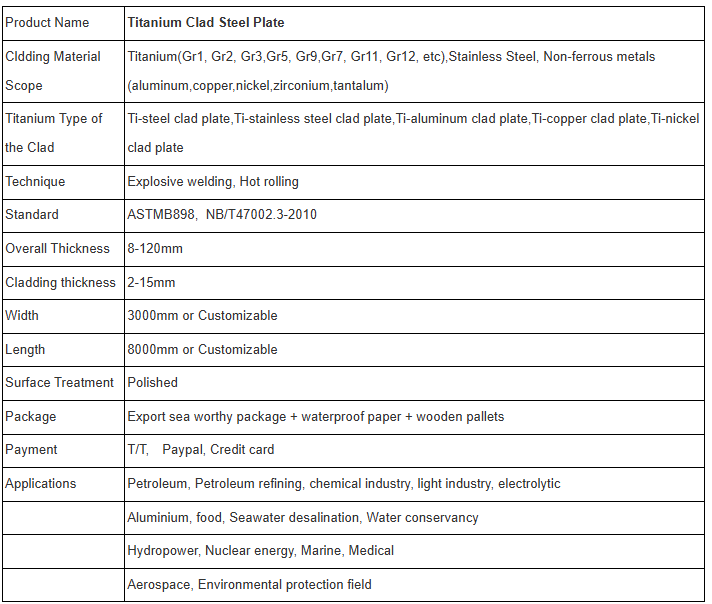

(Parameter of Titanium Clad Steel Plate)

Market Review

In recent times, with the healing of the worldwide economic situation and technological development, the need for titanium steel alloy plates has revealed a steady growth pattern. According to market research, the global titanium steel alloy plate market dimension has reached around US$ 5 billion in 2024 and is expected to reach around US$ 7.5 billion by 2028, with an average yearly substance growth rate of around 8%. This growth is mostly as a result of its irreplaceability in demanding applications and the boosting demand for much more effective and more secure materials.

Innovation advancement and development

Technical advancement is just one of the key elements driving the advancement of the titanium steel alloy plate market. Leading companies such as TRUNNANO continue to purchase research and development and are dedicated to boosting the performance of products, decreasing production prices, and expanding the range of applications. As an example, by optimizing the percentage of alloy parts and using sophisticated warm treatment procedures, the mechanical strength and corrosion resistance of titanium steel alloy plates can be significantly improved, making them execute better in severe settings. In addition, the application of nanotechnology has likewise brought new possibilities to titanium steel alloy plates, such as boosting surface firmness, improving conductivity and magnetic residential or commercial properties, and additionally broadening its application areas. With the constant development of modern technology, titanium steel alloy plates are expected to reveal their distinct worth in much more arising areas.

Growth of application areas

Titanium steel alloy plates have actually shown wonderful application potential in several markets as a result of their unique properties. In the area of aerospace, it is used to make aircraft architectural components, engine parts, etc, assisting to decrease weight and improve gas performance; in aquatic design, the corrosion resistance of titanium steel alloy plates makes it an optimal choice for constructing deep-sea boring platforms, ships Perfect for housings; in the automotive industry, with the fast development of the electrical car market, the demand for lightweight products is increasing, and titanium steel alloy plates have become a preferred alternative because of their superb performance; and in the medical area, as a result of their good organic Due to their compatibility and anti-infection abilities, titanium steel alloy plates are made use of to make clinical tools such as fabricated joints and oral implants, boosting the quality of life of patients. The growth of these application fields not just advertises the development of market demand yet also gives wide space for the advancement of titanium steel alloy plates.

Regional market analysis

From the perspective of regional circulation, the Asia-Pacific region is the globe’s biggest consumer market for titanium steel alloy plates, particularly China, Japan and South Korea. These three countries have strong production abilities in the areas of vehicle manufacturing, electronics market, aerospace and other areas, and are very important to state-of-the-art industries. Performance materials are in big need. The North American market is primarily concentrated in the aerospace and defense market, while the European market masters auto manufacturing and high-end manufacturing. Although South America, the Middle East and Africa currently have a smaller sized market share, due to the sped up automation process in these areas, the advancement of infrastructure building and construction and manufacturing is expected to bring new development points to titanium steel alloy plates. Distinctions in market characteristics and demands in various areas force business to adopt flexible market strategies to adapt to diversified market demands.

( TRUNNANO Titanium Clad Steel Plate)

Future fads and challenges

Looking to the future, with the continued recovery of the international economy and the rapid growth of science and innovation, the titanium steel alloy plate market will continue to keep a growth trend. Technical technology will continue to be the core driving pressure for market development, specifically the application of nanotechnology and smart manufacturing modern technology, which will better boost material performance, decrease prices, and increase the scope of applications. Nevertheless, the marketplace also faces some challenges, such as raw material rate fluctuations, high manufacturing costs, and magnified market competitors. In order to manage these challenges, companies such as TRUNNANO need to enhance investment in r & d, optimize production procedures, improve production efficiency, and, at the same time, reinforce collaboration with downstream clients to develop new products and check out new markets jointly. In addition, sustainable advancement and environmental management are also essential instructions for future development. By using environmentally friendly products and modern technologies, we can reduce power usage and waste exhausts throughout the manufacturing process to accomplish a great deal of financial and ecological benefits.

Supplier

TRUNNANOÂ is a supplier of nano materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you want to know more about stainless cladding, please feel free to contact us and send an inquiry.(sales8@nanotrun.com)

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us